|

Left: First Floor, Interlocking Machine Right: Second Floor, Panel |

|

|

Left: Cabinet of Sequence Switches. Right: Close-up view of Sequence Switch |

|

|

Both: Route Selection Keys |  |

|

Both: Auxiliary Sequence Switch Relays, located to the left of the Sequence Switches. |  |

|

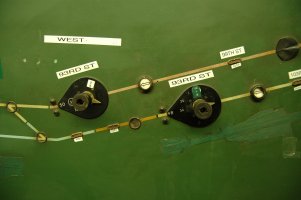

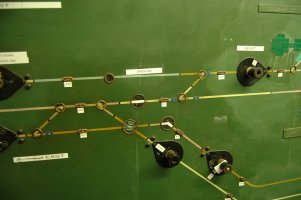

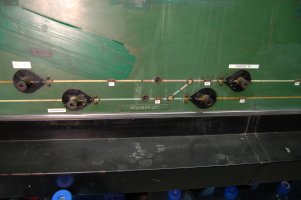

Both: Track Indicators and Switch Point Indicators on the Panel |  |

|

Both: Switch Point Control Keys at the top of the Panel. |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|